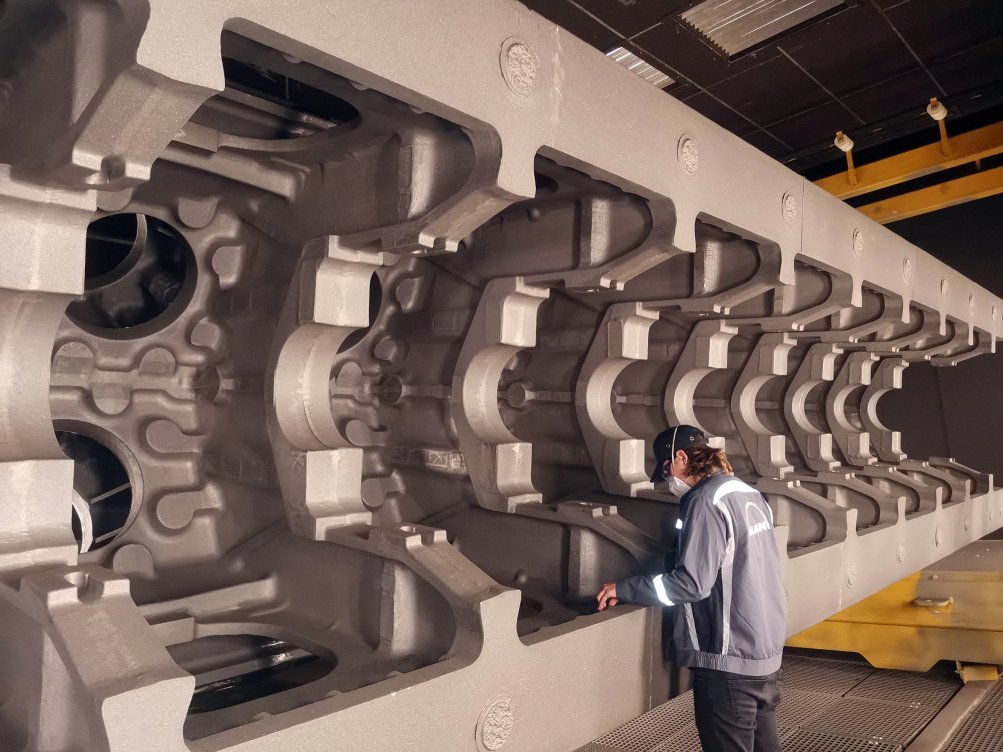

BLAST CLEANING EXTERIOR AND INTERIOR OF VARIOUS LARGE CASTINGS

BLAST CLEANING EXTERIOR AND INTERIOR OF VARIOUS LARGE CASTINGS

Case: MAN Energy Soltion GmbH Augsburg, Germany

MAN Energy Solutions GMBH is a global market leader and specialist for large diesel engines and turbomachinery.

BACKGROUND

The modernization of the blasting chamber at MAN Energy Solutions focused on automated processes, resource efficiency, and digitalization. This was successfully implemented with customized blasting robots and the latest programming software.

On the basis of experience in automation, MAN Energy Solutions had a clear picture of the possibilities of using Blastman robots for blast cleaning.

OBJECTIVES

The requirement was to blast clean automatically as well as in manipulator mode the exterior and interior surfaces of various large castings.

SOLUTION

Blastman delivered a new blasting chamber equipped with one Blastman B20S robot and one Blastman B20CS robot. Both robot arms are equipped with two 19 mm Venturi nozzles. The control cabin of the Blastman B20CS robot could be used for blast cleaning single or special workpieces in manipulator mode. The installation of Blastman enables the customer to create blasting programs with offline programming software on a PC, Point-To-Point via a hand-held teach pendant, and Teach-In method with the control cabin.

TECHNICAL INFORMATION

| Robot type | B20S & B20CS |

| Nozzles | 4 x 19mm (Venturi) |

| Blasting pressure |

8-10 bar |

| Abrasive | Mix of Steel grit and shot |

| Programming | OLP, PTP, Teach-In |

| Operation mode | Automatic & Manipulator |

RESULTS

The required automated blasting coverage was reached in the given cycle time and only some internal areas need manual touch-up. Due to the optimized blasting process of the Blastman robots, the customer is able to handle further castings of external partners.

You might be interested in these articles

Blog Posts Company News

13. Mar 2025

SUPPORTING GROWTH WITH AUTOMATED BLASTING

Company News Events

03. Mar 2025

Welcome to visit us at MECSPE, Bologna from March 5th to 7th.

Blog Posts Company News

12. Feb 2025

ROBOTIC ABRASIVE BLASTING IS AN EASIER CHOICE THAN YOU MIGHT THINK

Blog Posts Company News

22. Jan 2025

Leading the Future of Robotic Blasting

Blog Posts Company News Events

16. Dec 2024

Season´s Greetings from Blastman Robotics Ltd

Blog Posts Company News

26. Nov 2024

TAKING CARE OF AUTOMATED BLASTING SYSTEMS – BLASTMAN CUSTOMER SUPPORT AND AFTERSALES

Blog Posts Company News

22. Nov 2024