BLASTMAN GENERATION 4.0

BLASTMAN GENERATION 4.0

The original Blastman design has come a long way since 1982 when the first abrasive blasting robot was taken into use. In the year's robots have been transformed to completely servo-controlled, and the control system has been upgraded many times over to be more intuitive, informative, and user friendly. Now in 2021, Blastman Robotics is proud to present the 4th generation of automatic abrasive blast cleaning robots.

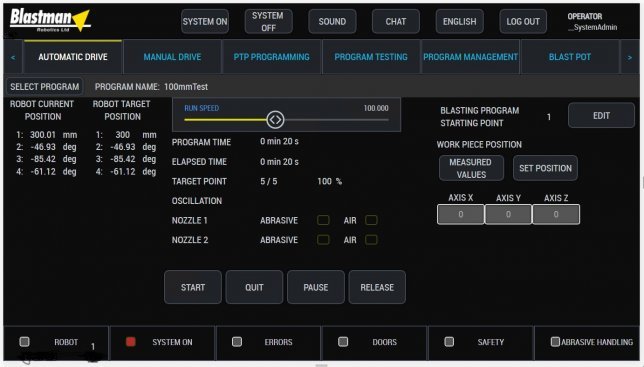

Guidelines for the design of 4th generation robots have been reliability, operability, and ease of use. The control system has been upgraded to include the latest and most advanced components on the market. The user interface has also been upgraded to be more informative and intuitive. The changes have been made to improve connectivity and reach the Industry 4.0 requirements of our customers. The user interface shows all the critical data for the robot and Blastman blast pot. The abrasive handling and ventilation systems can also be incorporated into the user interface to allow monitoring of each actuator and the condition of the equipment. This allows more in-depth logging history and real-time statistics for operations management to monitor and improve the process.

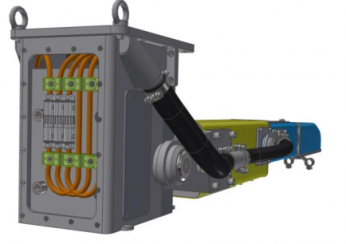

The mechanical and electrical design of the robots has also been upgraded. We have built on the same reliable structure, which has proven to last up to 25 years in operation. Special emphasis has been put into making the robot, even more, wear-resistant and making maintenance actions easier and more accessible. For the electrical design, we have incorporated OCT (one cable technology) for easier cable management and faster maintenance actions.

The 4th generation robots also have improved troubleshooting procedures and integrated manuals and guides built into the user interface.

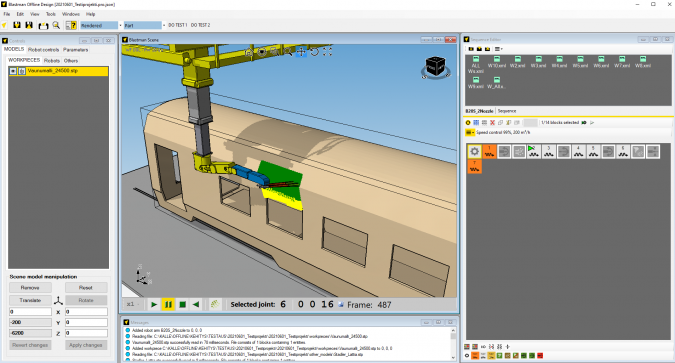

Blastman 4th generation robots still have three different programming methods: Teach-In, PTP via hand panel, and offline programming. The programming functions have been harmonized and vastly expanded, resulting in reduced time to set up robot operations.

The new generation robots are delivered with offline programming software as a standard. Offline programming software has been re-made to support Blastman robots specifically, allowing accurate blast simulations and automatic programming functions.

The first 4th generation robots have already been delivered and taken into operation. We have received very positive customer feedback and look forward to helping anyone to automate their blast cleaning process. Naturally, our support will continue for previous robot models as well. All older models will have an opportunity for a control system update if there is a need for it.

You might be interested in these articles

Company News

03. Apr 2025

BLASTMAN BLAST CLEANING ROBOTS IN DIFFERENT INDUSTRIES

Blog Posts Company News

01. Apr 2025

BLASTING ROBOTS PROMISE EFFICIENCY

Blog Posts Company News

13. Mar 2025

SUPPORTING GROWTH WITH AUTOMATED BLASTING

Company News Events

03. Mar 2025

Welcome to visit us at MECSPE, Bologna from March 5th to 7th.

Blog Posts Company News

12. Feb 2025

ROBOTIC ABRASIVE BLASTING IS AN EASIER CHOICE THAN YOU MIGHT THINK

Blog Posts Company News

22. Jan 2025

LEADING THE FUTURE OF ROBOTIC BLASTING

Blog Posts Company News Events

16. Dec 2024