Workpiece Abrasive Blasting

WORKPIECE ABRASIVE BLASTING – JOURNEY THROUGH THE ABRASIVE CLOUD

In our previous articles, we have often addressed the different aspects of the workpiece abrasive blasting process, but this time, we’ll take a full phase-by-phase journey from the workpiece's point of view. Before fastening your seatbelt for a ride into the blasting chamber, read first what options the workpiece has for entering the process.

Preparing for workpiece abrasive blasting

When a workpiece arrives for abrasive processing, the first step is to fit it and attach it to the selected transportation method that carries it through the actual blasting process. For this purpose, there are almost as many options as there are customers. The workpiece can enter the blast chamber with the aid of many kinds of conveyors, carts, or jigs. The piece can be hoisted on the transport solution with any kind of method, from a forklift to a ceiling crane.

Blastman can produce many types of transfer car solutions on its own. Transfer cars range from simple ones that can be pushed in with a forklift to more advanced systems with separate electric drives and rotating tables. More advanced transfer cars can be used efficiently for workpiece positioning and can act as an external axis for the robot, which can be programmed in the Blastman Studio offline programming tool. The weight and dimensions of customer workpieces affect the design of Blastman’s transfer cars, and all of them are always designed according to customer specifications – just as important as withstanding the robotic blast cleaning process.

However, Blastman’s blasting line doesn’t necessarily have to be fitted with its own transportation solutions. It can – and is in many cases smarter to – be combined with the customer’s existing method. This is often the case with workpieces transported between different manufacturing processes without removing them from the transfer system.

Workpiece abrasive blasting with the Blastman B20S robot and a customer's old transfer car system.

Regardless of the many possibilities in transportation methods, robotic abrasive blasting has certain requirements. Some of the key ideas of robotic blasting – especially when it’s automated – are repeatability and durability. For these reasons, the process requires accurate placement and blasting-related design. However, blast cleaning doesn’t require as precise placement as for example welding. Therefore, the tolerance for placement is measured in centimeters instead of millimeters. For special operations, Blastman also supplies machine vision systems to detect placement within less than a millimeter.

Workpiece abrasive blasting may commence

When the workpiece has been fastened on its transportation method, it enters a blast room or blast chamber. This is the home and domain of one or sometimes several blast-cleaning robots. Because of the amount of dust and the necessity for its ventilation, the space is solely dedicated to abrasive blasting. Blastman’s robots are specifically designed to handle the gruelling conditions of the blast chamber so that humans don’t have to.

In the Blastman’s process, the abrasive material is propelled against the surface of the workpiece with compressed air through larger hoses and almost twice as large nozzles as in any manual blasting method. This generates a lot of ricochets in the form of abrasive grain and its residue which makes the surroundings quite susceptible to wear. For this reason, the blast chamber is protected from the inside with rubber padding or polyurethane.

When a workpiece is inside a blast chamber, it can be blast cleaned with many methods or a combination of methods. For work safety and efficiency reasons, Blastman supports automatic robotic abrasive blasting with, if necessary, the aid of a manipulator-operated solution, which means manually operating a robotic arm from a control room or cabin. This solution is mainly necessary for specific individual needs during the otherwise automated process. The most suitable operation method depends on the specific characteristics of the workpiece and the availability of 3D models for programming the robots.

If a workpiece abrasive blasting necessitates it, the Blastman B20C-S has an additional control cabin with a separate gantry, which moves longitudinally with the robot.

Workpiece abrasive blasting in the good care of robots

In addition to simple, straightforward movement, the transportation solution for the workpiece abrasive blasting process can be designed or retrofitted to feature a rotating platform or a horizontal rotator with a combined position measurement system. This kind of technology is utilized, for example, in the treatment of wind turbine tower sections. This demands less movement from the robots around a workpiece and allows gaining more from the existing transport system.

Then again, it’s not like the robots would be unable to handle it – no more than they are eager to complain about the repetitive nature of their work. That is one of the main benefits of automated robotic blast cleaning: the robots always do the same work with the same consistent quality.

A solid example of this is the fact that on some occasions, wind power customers have been able to leave the cones of their windmill propellers unpainted after the blast cleaning process, as the smooth grey surface hasn’t necessitated any further treatment regarding color or quality.

Smooth sailing for the workpiece with easy programming

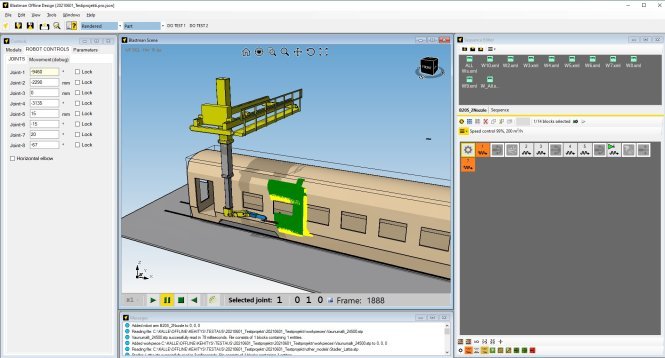

The key to enabling Blastman’s robots to achieve their famous surface quality is utilising the easy-to-use offline programming tool, Blastman Studio. With the tool, the workpiece is situated correctly, and the robot’s movement trajectories are guided around (or even inside) it in a virtual environment to create a blast cleaning program. The program can then be saved into a library on the robot user interface near the blast room.

Programming workpiece abrasive blasting with the Blastman Studio offline tool.

If a need to change something in the blasting process arises, for example, a change in the design of the workpiece, it’s possible to select the old program as a basis and modify it, as the necessary changes are often minor. Blastman’s robots also feature a manual panel that can be used for point-to-point programming, although the use of this method has significantly decreased since the launch of Blastman Studio.

When the desired program has been selected, one only needs to close the chamber doors and let the robots do their thing. When a program runs, the robots don’t require immediate human presence.

The larger or more complex the workpiece, the more useful it might be to utilize several separate programs. For example, a program for a train car is often created with separate programs for the sides, windows, front, and back end. These sub-programs are joined together to create one full program. The benefit is that these sub-programs can be utilized for other types of cars and program modification is easier in case of design changes for the end product.

Other important factors are the software's copy/paste and mirroring functions. In the case of a train car, the sides of the car are identical. Therefore, one only needs to create a single program for one side and copy/mirror it to the other side. This significantly reduces programming time and allows identical movements between the two sides, resulting in high and consistent quality.

You shall pass

Depending on the setup of the processing line, a blast-cleaned workpiece is transported either to another chamber/workstation or out of the hangar. Several workstations chained together are not exactly common, but these kinds of solutions exist. This kind of setup might consist of robotic abrasive blast cleaning, a platform for manual touch-up blasting, and finally, a platform for manual vacuuming and other cleaning. This allows for individual rooms to be used for exact processes, further minimizing the workpiece throughput time.

What is more typical is utilizing the blast cleaning robots themselves for cleaning purposes. Blastman’s solutions use pressurized air, remember? This enables leaving out the abrasive material which essentially turns the blast robots into blowers. When the blasting program ends, the blowing program can take off instantly and, with the aid of the blast chamber’s vacuuming and ventilation solutions, leave the surface of the workpiece nice and clean. As blowing compressed air is not free, Blastman robots have a built-in system that automatically reduces the pressure for cleaning programs. This makes the overall process more optimal and cost-efficient.

This is not to say additional cleaning wouldn’t ever be needed. Vacuum systems, especially inner cleaning, are often very useful with spots that can be cleaned to some extent by blowing, but not completely. For example, the floor spaces of train cars can be very compartmentalized.

In a way, Blastman can be fairly called an engineering house, although it is, first and foremost, an OEM. So far, the vast majority of Blastman’s solutions have concentrated on abrasive blasting, but considering a workpiece's journey through its surface treatment process, some other interesting phases, such as metallization, have also been visited. The company can assume the role of an overall supplier and has, in fact, supplied complete surface treatment lines.

Future adventures of the blast-cleaned workpiece

Throughout its existence (and even before that), Blastman has been at the leading edge of not only the design and development of automatic robotic abrasive blasting but automation itself. A recent example of this is Blastman’s installation of the world’s largest robotic abrasive blast cleaning line and the continuous development of part-scanning, machine vision, and automatic programming systems.

Watch the video of the World´s largest blast-cleaning robot.

To date, Blastman has been able to automate the whole process, which begins with a workpiece entering a blast chamber and ends when the piece is brought out with a clean surface ready for use or further treatment.

Blastman is highly motivated to develop automated solutions further. The company is also tightly invested in the Industry 4.0 movement to be a solid part of even longer uninterrupted automated production and logistical chains. It is exciting to see how long the continuous automated journey of a workpiece will eventually become.

Read more about the future possibilities of workpiece abrasive blasting.

You might be interested in these articles

Blog Posts Company News

26. Nov 2024

TAKING CARE OF AUTOMATED BLASTING SYSTEMS – BLASTMAN CUSTOMER SUPPORT AND AFTERSALES

Blog Posts Company News

22. Nov 2024

BLAST CLEANING IN THE SPEARHEAD OF AUTOMATION – THE FUTURE OF ABRASIVE BLASTING

Blog Posts Company News

21. Oct 2024

BLASTMAN STUDIO - OFFLINE PROGRAMMING TOOL

Blog Posts Company News

18. Oct 2024

BLASTING AUTOMATION AND ROBOTICS ENABLE THE BEST BLAST CLEANING EFFICIENCY

Blog Posts Company News

17. Sep 2024

Robotics in pre-treatment

Company News

11. Sep 2024

OFFSHORE BARGE REPAIR AND MANUFACTURING

Company News Events

23. Aug 2024